2973 Harbor Blvd, #665, Costa Mesa, CA 92626

tel: 831-287-0495

Lasercheck® Surface Finish Sensor Heads & Controllers

Ra Surface Roughness Measurement Products

Lasercheck® Surface Finish Measurement Sensor Heads

Two versions of Lasercheck® sensor heads are available to optimize for specific measurement requirements of size, handling and mounting tolerances. The surface roughness measuring heads can be combined with any controller also best suited for specific measurement requirements.

| Model 8826 Lasercheck® Surface Finish Sensor is our smallest surface finish sensor head, just 25 x 19 x 52 mm. It is best used for portable measurements. Fits in tight locations such as journal and lobes on automotive crankshafts and camshafts. The 8826 head is very convenient for quick checks of finish of a variety of cylinder shapes and flat measurement surfaces. | |

| Measuring range: 0.0325 to 1 micron (1.50 - 40 micro-inch) | |

| Mechanical size: 25.1 x 19.1 x 52.2 mm (0.99 X 0.75 X 2.055) | |

| Controller compatibility: Automated (Auto or A Model), and OEM Model | |

| Features: Portable, Light & Durable, Measures any material, Fits in tight spaces | |

| Model 6212 Lasercheck® Surface Roughness Sensor is the most rugged surface finish sensor in the world. It is commonly used for non-contact automated post-process automated inspection. Mounted on machinery and run by Lasercheck® automated controllers. It never needs recalibration, eliminating the need for maintenance, repair, and recalibration costs. | |

| Measuring range: < 0.025 to 1 micron (<1.0 - 40 micro-inch) | |

| Mechanical size: 76.2 x 35.6 x 44.4 mm (3.00 X 1.40 X 1.75") | |

| Controller compatibility: Automated (Auto or A Model), and OEM Model | |

| Features: Rugged, compact, easily mounted in production settings for automated finish monitoring | |

| Model 5872D Lasercheck® Surface Roughness Sensor provides all the benefits and automation capability of the Model 6212 Lasercheck® Surface Roughness Sensor in a larger format package in applications where space is available. This provides maximum standoff distance from the measurement surface and resulting simpler setup and maintenance. | |

| Measuring range: < 0.025 to 1 micron (<1.0 - 40 micro-inch) | |

| Mechanical size: 304.8 x 139.7 x 139.7 mm (12.00 X 5.50 X 5.50") | |

| Controller compatibility: Automated (Auto or A Model), and OEM Model | |

| Features: Rugged, enhanced (maximum) distance from measurement surface, easily mounted in production settings for automated finish monitoring | |

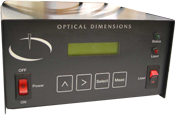

Lasercheck® Surface Finish Measurement Controllers

Three versions of Lasercheck® controllers are available to optimize for specific measurement requirements of automation options, user interface and flexibility.

| Lasercheck® "Auto" Version controller provides user friendly manual operation with capability to configure for automated measurements. Windows® based LCD touch screen control provides easy to follow setup and manual operation capability. Can accept trigger inputs from external sensors or production equipment for automated inspection applications. USB, RS232, Ethernet, and failed part output indicators. | |

| Mechanical size: 176 x 38 x 114 mm (6.9 x 1.5 x 4.5") | |

| Sensor compatibility: Model 8826, Model 6212 | |

| Features: Windows® CE interface provides user frendly operation. | |

| Lasercheck® "A" Version Automated Controller is optimized for 100% automated surface finish measurement of surfaces. Powerful electronics provide high speed and high repeatability. Accepts trigger inputs from external sensors or production equipment. Numerous options for monitoring by users and remote computers and production equipment include RS232 streaming, 4-20mA / 0-10 Volt, and failed part output indicators. | |

| Mechanical size: 203 x 229 x 105 mm (8.00 x 9.00 x 4.15") | |

| Sensor compatibility: Model 8826, Model 6212, Model 5872 | |

| Features: Fast and high repeatability electronics. Optimized for automated inspection | |

| Lasercheck® "C" Version OEM Card Controller is for manufacturers of automated gaging and machine tool equipment. It is integrated directly into electronic manufacturing or testing equipment used on the factory floor. This controller includes intergrated firmware burned onto onboard processor which provides roughness values in ASCII format through an RS232 interface. User creates their own interface, control, and data capture software. Full documentation with communication protocol commands provided to aid programmer designing application specific software. | |

| Mechanical size (including connectors: 85 x 85 x 15 mm (3.35 x 3.35 x 0.6") | |

| Sensor compatibility: Model 8826, Model 6212, Model 5872 | |

| Features: Power, RS232, and I/O cable connectors provided. | |

Lasercheck® Surface Finish Acceessories

Accessories are available for Lasercheck® Measurement Heads and Controllers to enhance capabilities, ease of use, special alignment needs, mounting, and integration into user processes and machinery.

Lasercheck® Discontinued Products

Optical Dimensions provides service, repair, certification for all models of Lasercheck® products. (Note: parts availability dependent)

Please Visit The: Sales and Support section or Please Visit The: Downloads section for technical and support information for Lasercheck® products no longer offered by Optical Dimensions.Product Infromation Available: 5872 (2002 and earlier Version), 5872C Sensor, Windows Software control.