2973 Harbor Blvd, #665, Costa Mesa, CA 92626

tel: 831-287-0495

Lasercheck® Surface Measuring Technology & Capabilities

How does Lasercheck® Work and How Can Lasercheck® Work For You

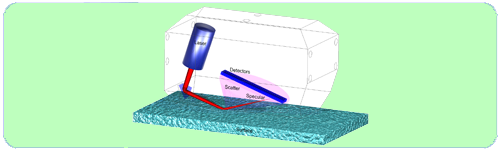

Lasercheck® sensors instantly measure reflection of an internal laser illuminating a surface. Patented Surface Roughness Measurement sensor technology analyzes shape and distribution of the laser signal reflected from the surface. Proprietary software and calibration routines convert the signal into Ra roughness of the surface.

Perfectly smooth surfaces with no roughness reflect a clean specular laser beam. As surfaces become progressively rougher, less laser reflection occurs in the specular direction, more diffuse laseer reflection occurs in other directions depending on the microstructure and degree of surface roughness.

Lasercheck® on 3 Different Surfaces - Perfectly Smooth with No Roughness, 2D Roughness Pattern, 3D Roughness Pattern

Lasercheck® measures over a defined roughness range (< 0.025 to 1 micron / <1.0 - 40 micro-inch). The unique patented technology provides exceptional precision and repeatability on lower Ra surface finish ranges (< 0.025 to 0.25 micron / <1.0 - 10 micro-inch).

Lasercheck® may require setup, alignment, or aid of fixture for measuring surfaces in some applications. After setup, measurements are extremely rapid, easy and reliable making Lasercheck® optimal for operations producing high volume of identical or similar surface types and shapes. Low volume or job shop opearations involving multiple different parts may not benefit due to frequent setup changeover time and effort.

Easy to use fixtures for quick, easy, repeatable setup on simple surface shapes - cylinders of almost any diameter, and large flat surfaces are available.

Surface Structure (Topography) Lasercheck® Surface Roughness Gages Measure

Lasercheck technology is capable on surface types created by specific fnishing operations which create a surface that is fractal or "random" in it's microscopic structure as shown below.

|

|

The upper image to the left depict random fractal finsh structures produced by a directional "2D" finishing operation such as cylindrical grinding or belt sanding. Lsaercheck is capable of providing excellent measurement results on surfaces that exhibit this structure. |

The middle image to the left depict random fractal finsh structures produced by a directional "3D" finishing operation such as orbital sanding or grit blasting. Lsaercheck is capable of providing excellent measurement results on surfaces that exhibit this structure.

|

|

The lower image to the left depict structured finsh structures produced by a finishing operation such as turning on a lathe or milling. These surfaces differ from the example surfaces above having repeating groves or scratches, identifiable structure, is not random. Lasercheck is not capable of measuring surfaces that feature groves, scratches, repeating patterns such as these. |

|

Surface Shapes Lasercheck® Surface Roughness Gages Measure

|

|

The upper image to the left depicts a simple flat surface with no groves or obstructions. Lasercheck is easily focused and aligned to measure on large flat areas. Once aligned the surface can be moved under the Lasercheck sensor at any speed to rapidly scan Ra roughness over a large portion.

|

The middle image to the left depict simple cylinder shapes. Lasercheck is easily focused and aligned to measure Ra on cylinders of almost any length or any diameter. Once aligned the cylinder can moved lengthwise and / or rotated under the Lasercheck sensor at any speed to rapidly scan Ra roughness along the length and around the circumference of the cylinder.

|

|

The lower image to the left depict a more complex shaped pinion gear. This surface contains gear face, groves, spirals, recesses. All complex features and areas Lasercheck cannot be focused or aligned to. Lasercheck is not suited for measurement of parts like this due difficult to access surface locations such as inside holes, groves, parts with multiple steps, diameters, bevels. |

|

Lasercheck® Ideal Applications

The Best Suited Finishing Operations include most types of surface grinding (especially cylindrical grinding), belt sanding, most polishing and superfinishing operations, many forms of sand blasting.

Exceptional Precision Results are in low Ra ranges. Lasercheck® monitors highly finished surfaces with low Ra values (< 0.025 to 0.25 micron / <1.0 - 10 micro-inch) with unmatched performance, precision, repeatability.

The Best Suited Shape of surfaces are large flat areas, and finish on OD of cylinders of almost any diameter or length. Complex shapes, groves, holes, tapers, multiple steps and related are generally not possible.

The surface being measured must be Clean and Dry for reliable, accurate measurements. In automated post-process measurement applications most cutting and cooling fluids that are primarily water based, pressurized air through a nozzle directed at the surface will adequately dry and clean. As cutting fluid and coolant become primarily oil based, pressurized air will not adequately dry and clean.